Product Description

HS-CJ8 Computerized Mattress Panel Cutting Machine

1. It can be used together with quilting machine or alone.

2. It can cut automatically according to customer's requirements, such as cutting pieces, strips, edges and rolling cloth.

3. It is infrared controlled, safe to operate and has high cutting precision.

4. Cut length and width realize electric fixed-length adjustment, and the operation is more user-friendly.

5. The feed is increased with a synchronous pressing roller, the pressure is uniform, the feed is flat, and the slitting is smoother, especially the thin material is easier to trim.

6. The conveyor belt is used for discharging, which is convenient for stacking and saves labor.

7. Box shape, optimized design, improve the running speed of the whole machine and the quality of the cutting knife, and the cutting efficiency is higher.

Product Function

2. The feed is increased with a synchronous pressing roller, the pressure is uniform, the feed is flat, and the slitting is smoother, especially the thin material is easier to trim.

3. The conveyor belt is used for discharging, which is convenient for stacking and saves labor.

4. Box shape, optimized design, improve the running speed of the whole machine and the quality of the cutting knife, and the cutting efficiency is higher.

Technical Parameters

| MODEL | HS-CJ8 |

| DIMENSION(L*W*H) | 3500×3300×1750mm |

| GROSS WEIGHT | 1000kg |

| OUTFEED PLATE LENTH | 2400mm |

| CUTTING THICKNESS | 5-60mm |

| CUTTING WIDTH | 100-2400 |

| OUTPUT | 8000mm/min |

| POWER | 2KW |

| VOLTAGE | 380V/220V/50HZ |

| AIR PRESSURE | 0.4-0.8Mpa |

Product Details

2. The feed is increased with a synchronous pressing roller, the pressure is uniform, the feed is flat, and the slitting is smoother, especially the thin material is easier to trim.

3. The conveyor belt is used for discharging, which is convenient for stacking and saves labor.

4. Box shape, optimized design, improve the running speed of the whole machine and the quality of the cutting knife, and the cutting efficiency is higher.

Manufacturing Capacity

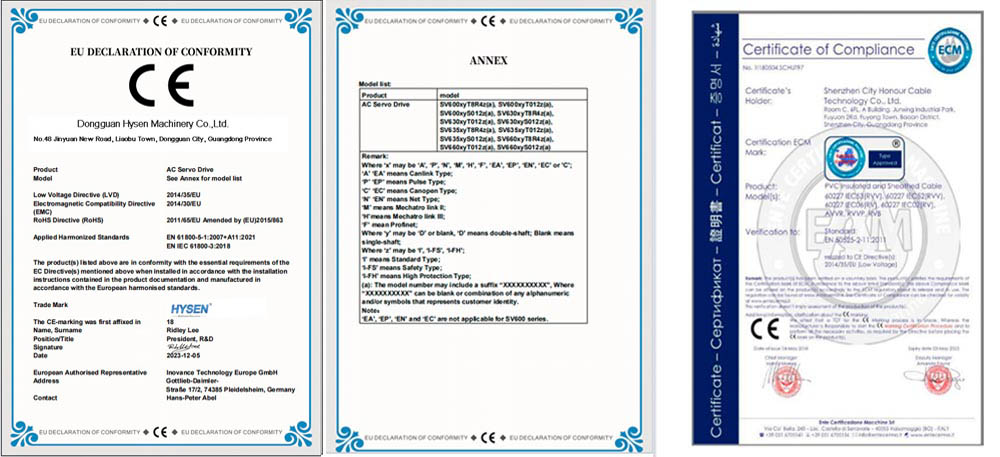

Honor Certificate

+8618818776182

+8618818776182

+8618818776182

+8618818776182