Product Description

HSY64 Computerized shuttle quilting machine, Mattress Machine, the needle rows are constructed with iron bar frame, no need to add oil to avoid oil contamination of fabrics. This structure is more solid and not easy to be damaged, low maintenance cost.

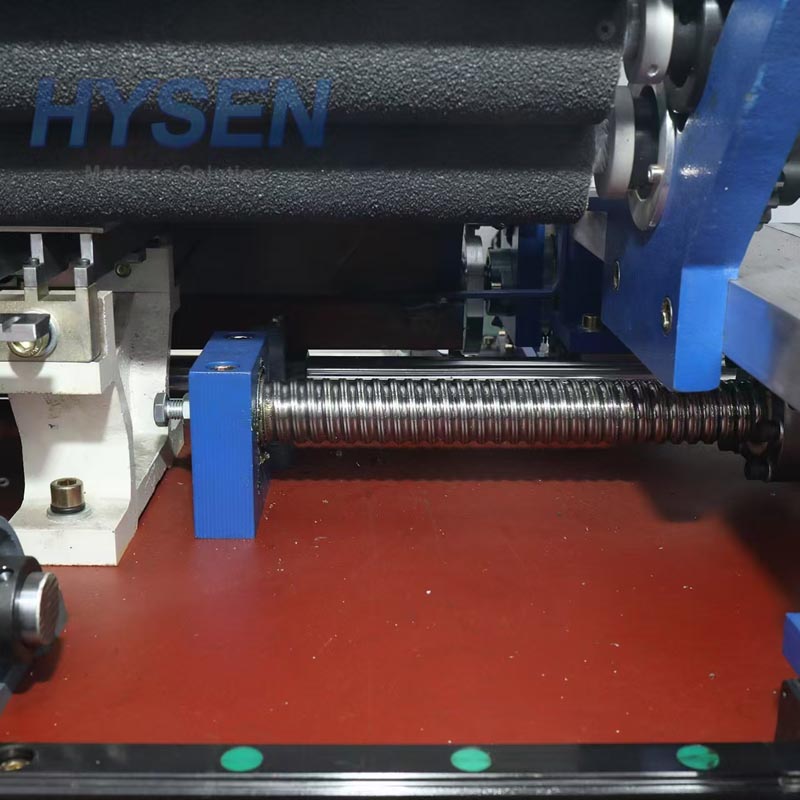

The saddle frame and roller are servo-driven.

The main shaft adopts frequency conversion control device.

Computerized speed control, needle speed up to 1000 r/m, stitch length 2mm-6mm set at will.

Multiple times across quilting (covering 360 degree and 180 degree quilting patterns)

Advanced and practical thread breakage detection technology for the surface thread, automatic stop function for thread breakage.

Hand feeling close to infrared sensor, make your operation safer.

Adopt CAD drawing method, precise graphics, convenient and quick.

Running status detection and prompting, the operation of the machine is clear at a glance.

Four-axis drive machine is more solid performance is more stable.

Product Function

1. The needle row adopts a needle bar frame structure and without refueling to avoid greasy fabric.Moreover, the structure is solid and not easily damaged, low maintenance costs.

2. Advanced and practical up thread-break detection technology,auto-stop when thread-breaking.

3. The saddle and roller are driven by servo and the main shaft is controlled by frequency converter.

4. The four-axis actuator is more solid and stable performance.

5. Easy preparation of CAD drawings extremely precise.

Technical Parameters

| MODEL | HSY64 |

| DIMENSION(L*W*H) | 3750x2450x2550mm |

| QUILTING WIDTH | 1600 |

| SPACE BETWEEN NEEDLE ROWS | 76.2 |

| SPACE BETWEEN NEEDLES | 25.4 |

| X-AXIS MOVEMENT DISPLACEMENT | 305 |

| QUILTING THICKNESS | ≤30mm |

| STILCH LENGTH | 2‐6 |

| PRODUCTION SPEED | 70-180m/h |

| MODEL OF NEEDLE | 14#/16#/19# |

| MAIN SHAFT SPEED | 400-1000RPM |

| POWER | 6KW |

| VOLTAGE | 380V/50H 220V/60H |

| GROSS WEIGHT | 4000Kg |

Product Details

|

|

| Advanced and practical up thread-break detection technology,auto-stop when thread-breaking. | The saddle and roller are driven by servo and the main shaft is controlled by frequency converter. |

|

|

| Multiple cross quilting (covering 360-degree and 180-degree quilting patterns) | Easy preparation of CAD drawings extremely precise. |

Application Range

Manufacturing Capacity

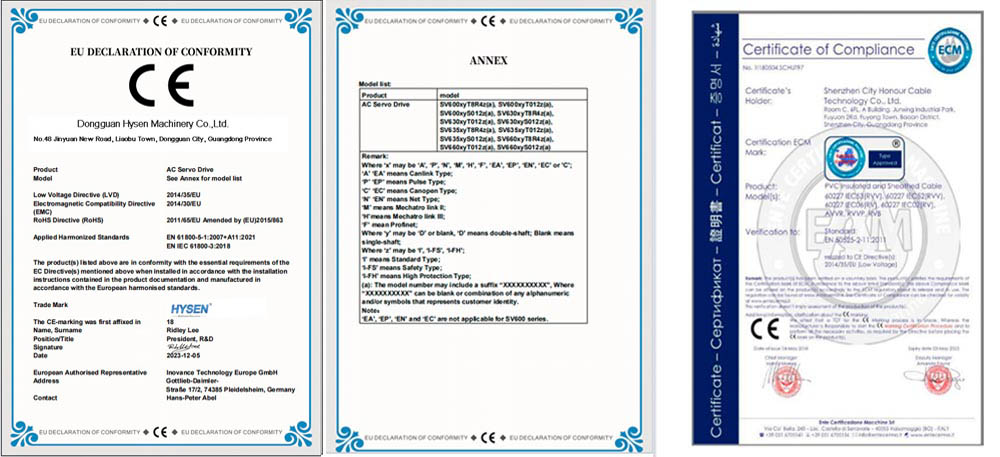

Honor Certificate

+8618818776182

+8618818776182

+8618818776182

+8618818776182